Sensors for the hydrogen economy

SENSORS FOR THE HYDROGEN ECONOMY

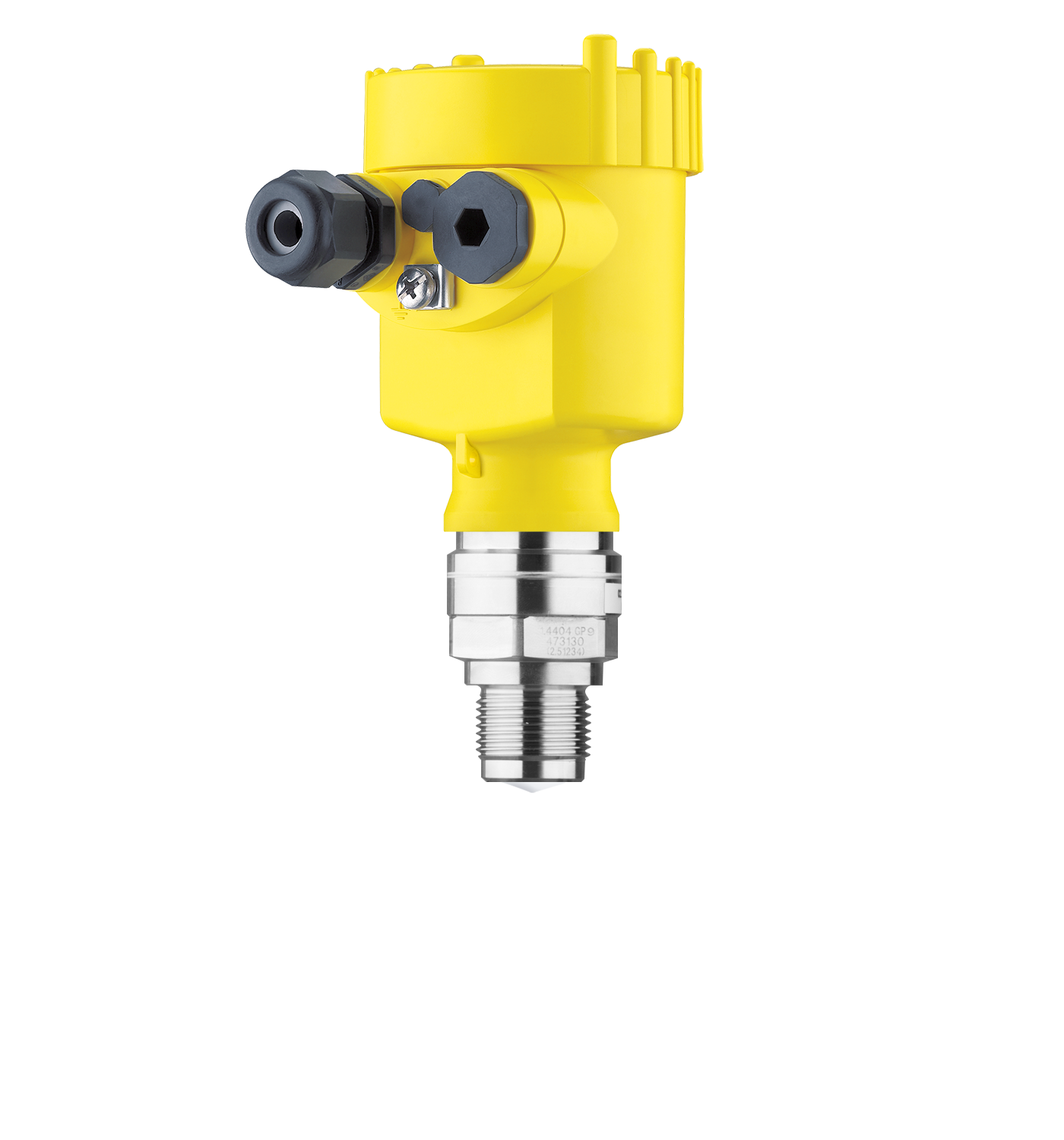

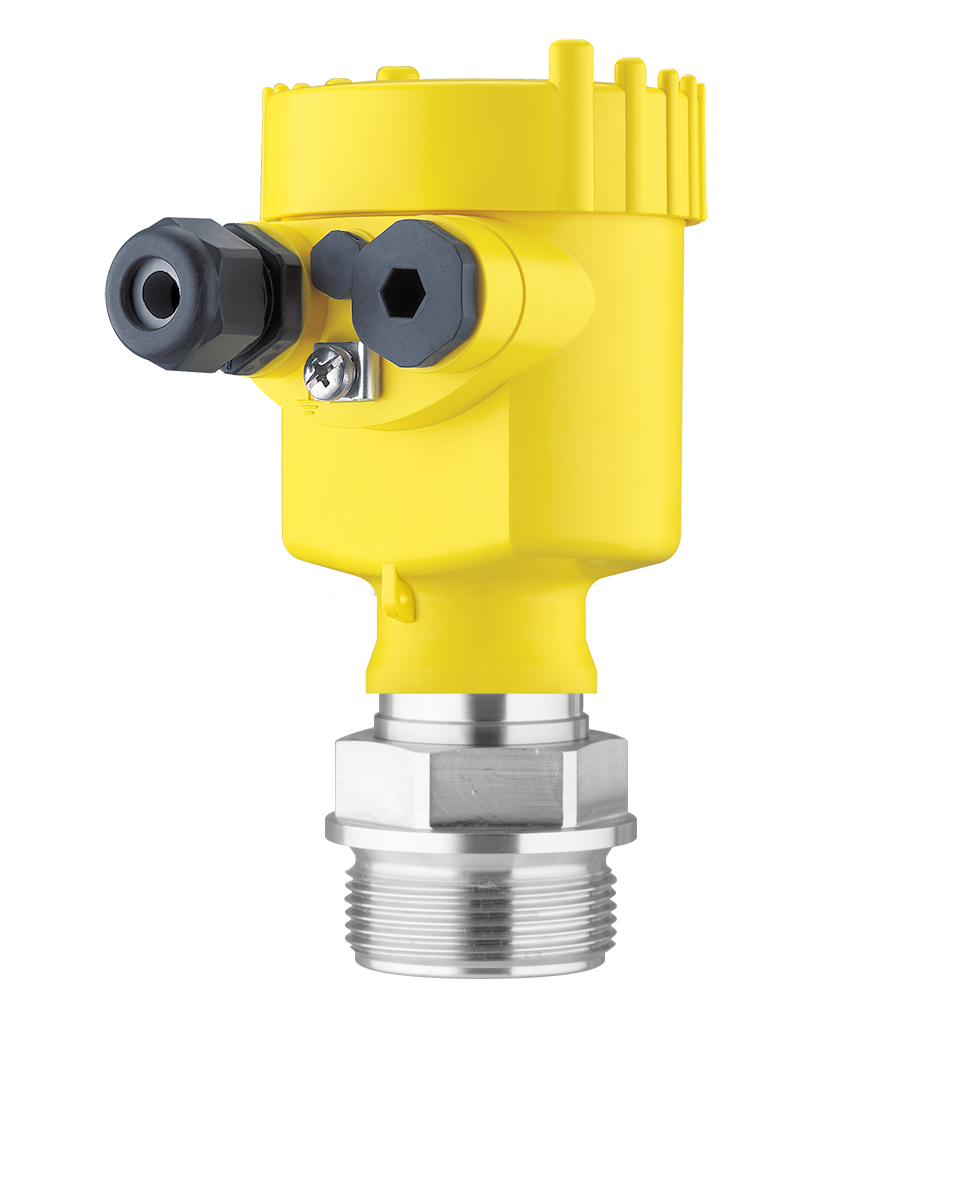

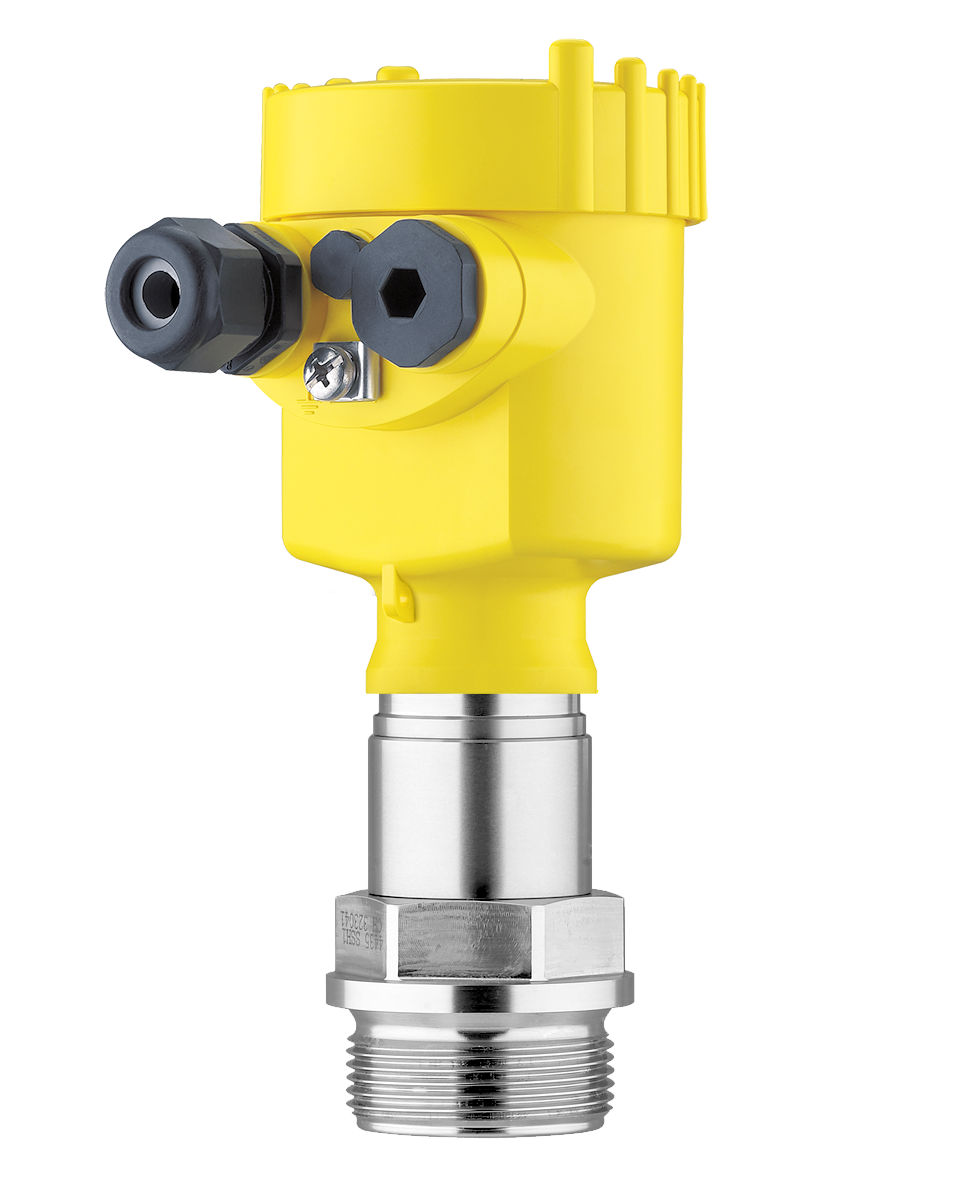

VEGA’s level sensors reliably measure the level in hydrogen tanks and containers and warn of overfilling, underfilling or leakage. They deliver reliable measurement results, even when operating with small measurement ranges. Tank internals do not impair the accuracy of the readings.

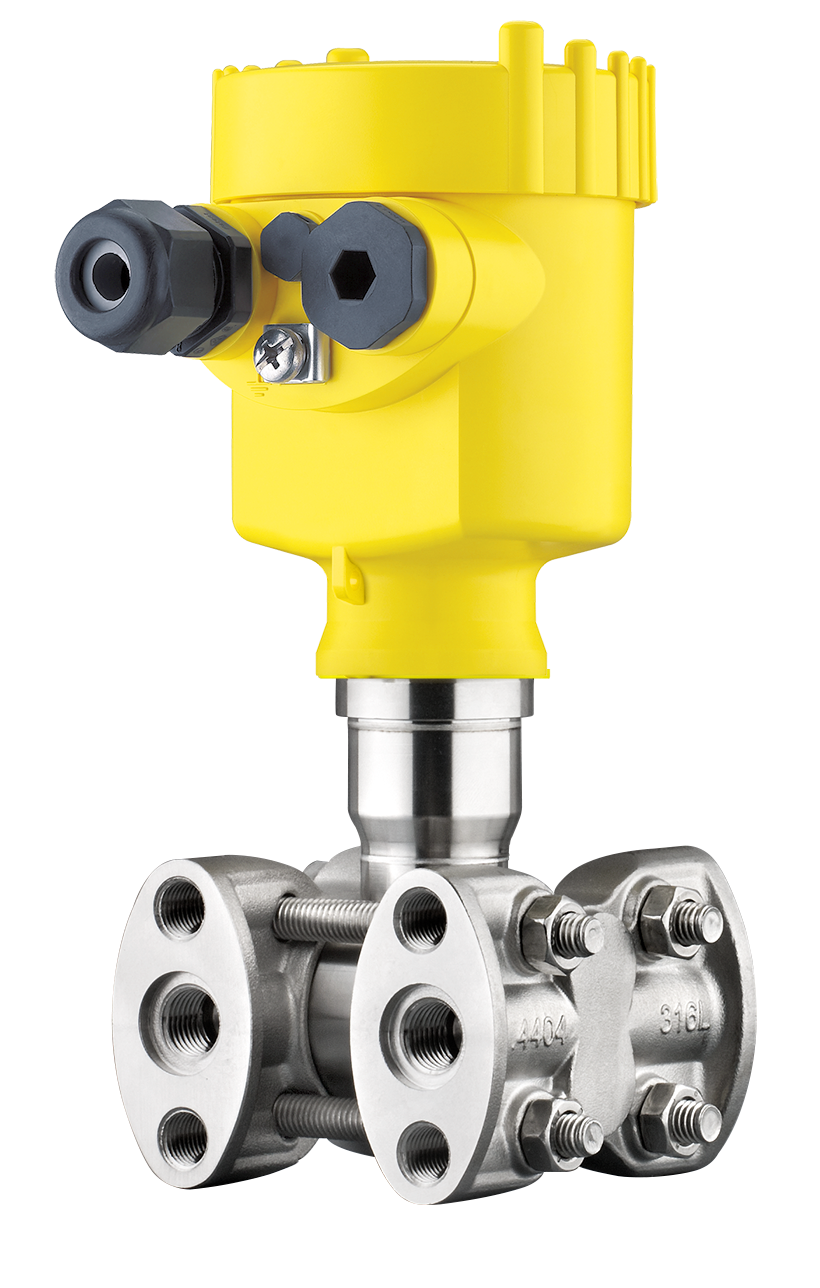

VEGA’s pressure sensors measure the pressure of hydrogen gas in pipelines, containers, tanks and other handling systems. They ensure long-term stability measurements and are especially easy to set up and put into operation.

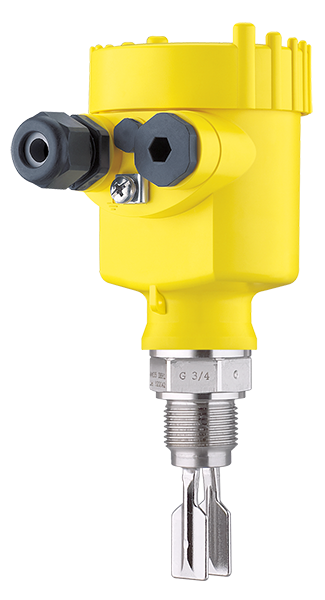

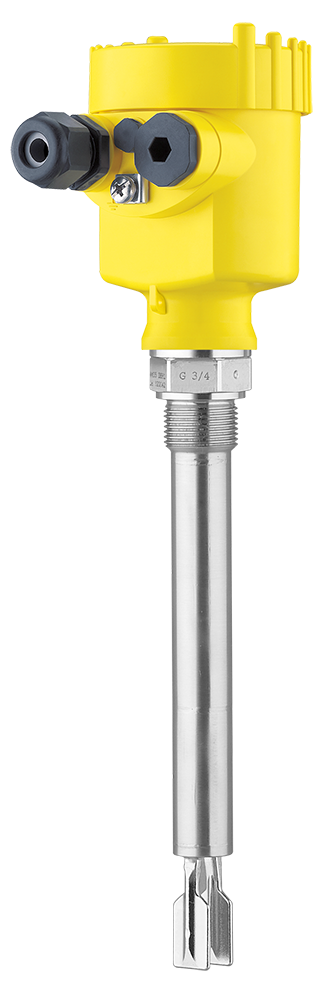

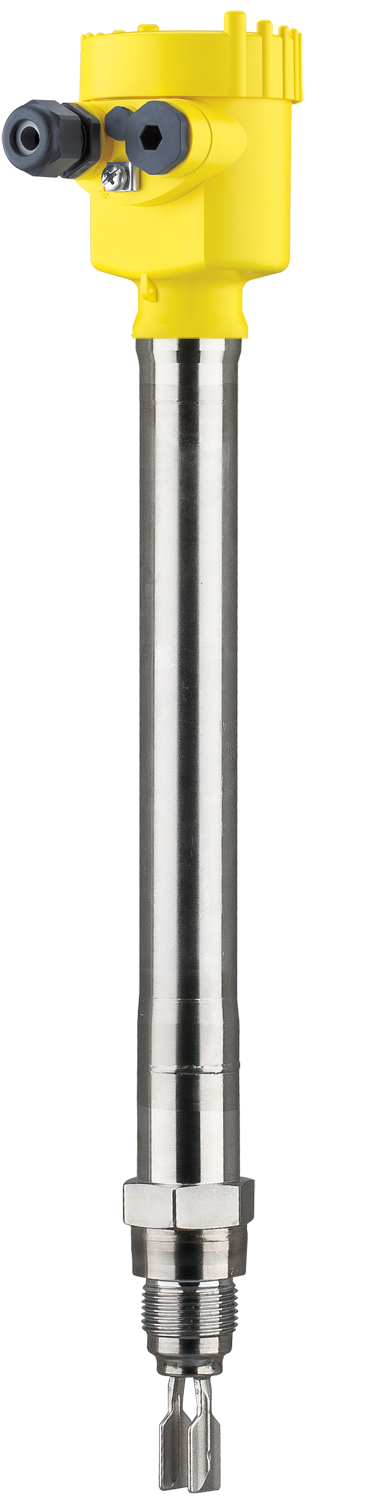

VEGA’s point level sensors detect the limit level in hydrogen tanks and containers. They ensure maximum reliability and safety in all hydrogen applications.

Personal consultant

Enter your zip to find your personal consultant.

{{contact.DisplayName}}

{{contact.StakeHolderType}}

Callback service

Ask for one of our experts to call you back.

Request a return callIn urgent service cases, please contact us directly via our 24-hour service hotline.

Close