VEGA sets new standards with VEGAPULS 6X

VEGAPULS 6X: One radar sensor for all applications

With VEGAPULS 6X, VEGA is literally revolutionising radar level measurement. The great advantages of the instrument can be quickly summarised:

- Fast configuration

- Simple setup and commissioning

- Highest security standards

- Simple operation

Is deciding which instrument is the right one, too complicated? No longer!

Whoever has a choice, is blinded by choice – VEGA makes this well-known issue obsolete: The leading manufacturer of level, switching and pressure instrumentation has developed a radar sensor that’s a perfect fit for all applications: VEGAPULS 6X.

So, is it "one for all"?

VEGAPULS 6X delivers precise measuring results – no matter whether in liquids or bulk solids, or under adverse conditions like high temperature, dust or extreme pressure. Even

- tight spaces,

- aggressive media like chlorine,

- condensation or

- deposits on the sensor

do not affect the measuring result. The instrument is always just right for the application it’s needed in: With the help of the configurator, users can easily put together a sensor that fulfils their particular needs with just a few mouse clicks. They don’t have to worry about things like operating frequency, suitable connection or DK value of the medium. Setup and commissioning is also simple: If all the details of the application are known, the sensor can be preset so that it only needs to be mounted and electrically connected.

What about safety considerations?

How does communication work?

There are several different ways to adjust the instrument: For sensor adjustment directly at the measuring point, VEGA has provided the proven PLICSCOM display and adjustment module , whose menu structure is designed to be clear and easy to understand. The level sensor can also be adjusted via a PC or laptop with PACTware. And lastly, the VEGA Tools App offers a wireless adjustment option using Bluetooth on a smartphone or tablet.

The most important technical data:

- Process temperature: -196° to +450° C

- Process pressure: -1 to +160 bar

- Measuring range: 120 metres

- Measuring accuracy: +/- 1 millimetre

✅ One radar sensor for all applications: VEGAPULS 6X | VEGA talk

Does all that make VEGAPULS 6X the ideal sensor for level measurement with radar? Yes, for sure!

Related applications

Chlorine storage tank

Level measurement and point level detection in storage tanks for chlorine

Chlorine production and storage places high demands on the chemical and the diffusion resistance of the materials in the production equipment. Extensive process knowledge and experience is required when selecting the sealing materials. In fact it is decisive for the long-term, safe and profitable operation of the plant. Since the processes can only be interrupted at great expense and plant disruption, the reliability of the instrumentation is a top priority.

Reliable

All materials are fully chemically resistant

Cost effective

Universal application, independent of product characteristics and process conditions

User friendly

Maintenance-free operation

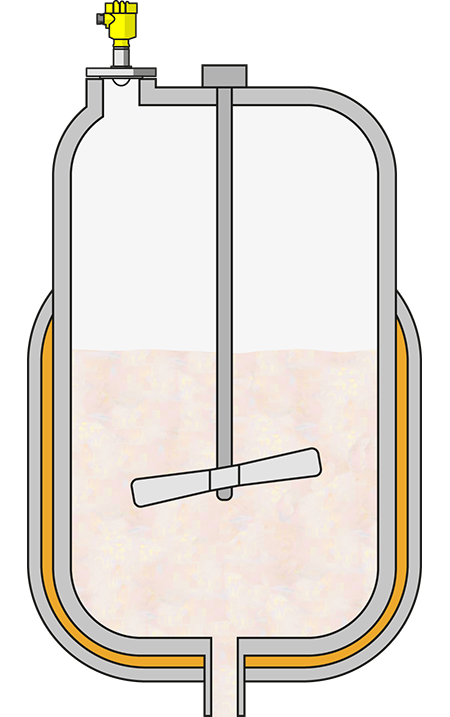

Reactor

Level measurement in an aluminium powder suspension reactor

Aluminium powder suspension is an intermediate for titanium sponge production. In the reactor, vanadium oxide trichloride is removed from the aluminium powder suspension. When the aluminium powder suspension is fed into the reactor, strong turbulence arises on the product surface. To optimize the process, the level in the reactor must be accurately measured and monitored.

Reliable

Reliable measurement despite small dielectric constants

Cost effective

Reliable measurement of the entire reactor volume

User friendly

Simple mounting and setup

Related products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}