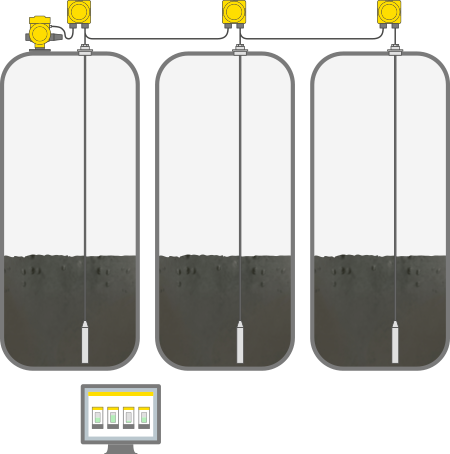

VEGA Inventory System

VEGA offers a system for optimal inventory management: VEGA Inventory System.

Data acquisition, clear visualization and efficient logistics are the core elements of successful, automated inventory control.

The interaction between measurement technology and software plays an important role.

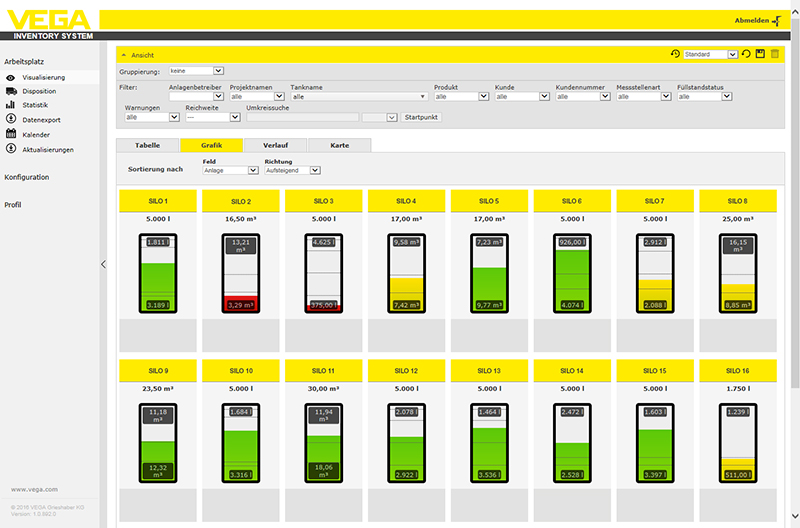

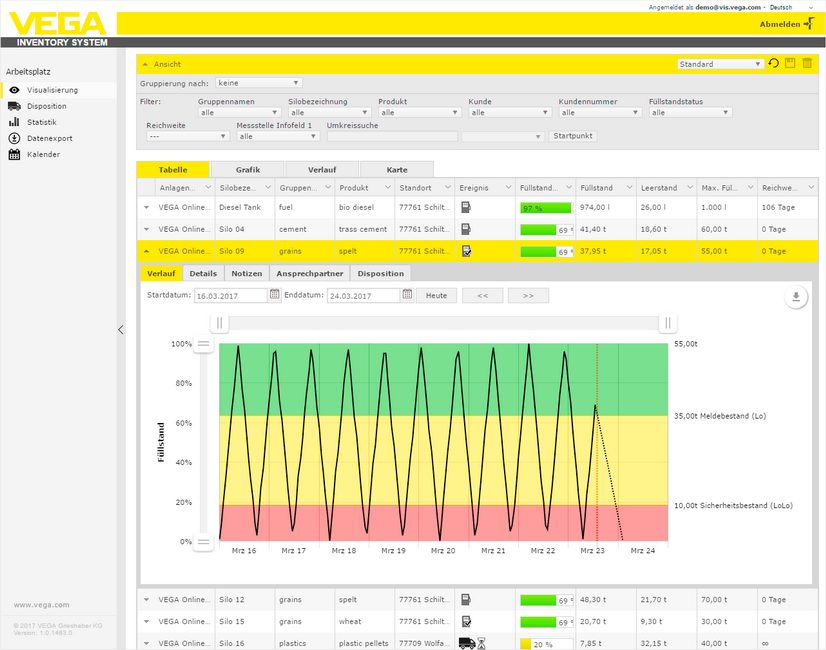

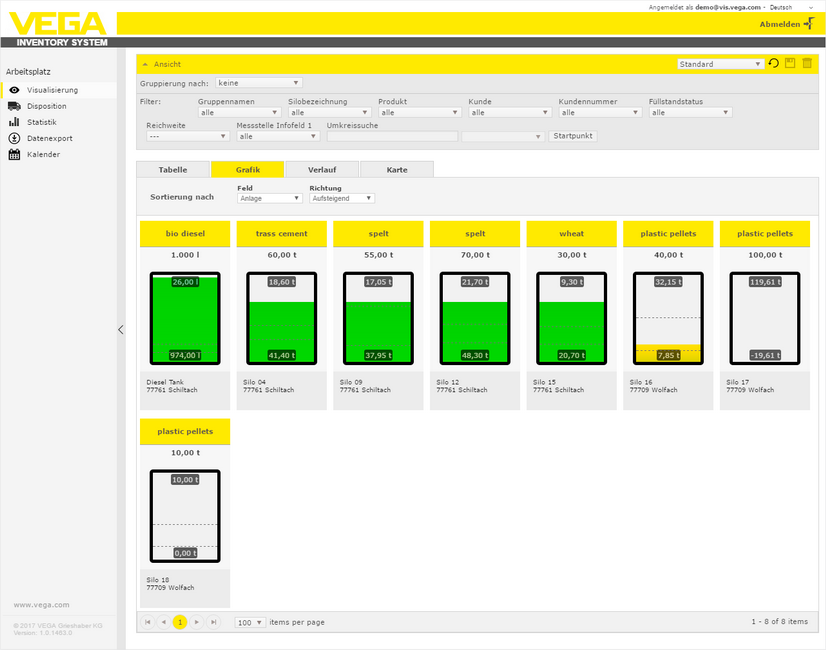

2. Visualization of measurement data

Bar charts and tank graphics provide the user with a clear and constant overview of current stock levels.

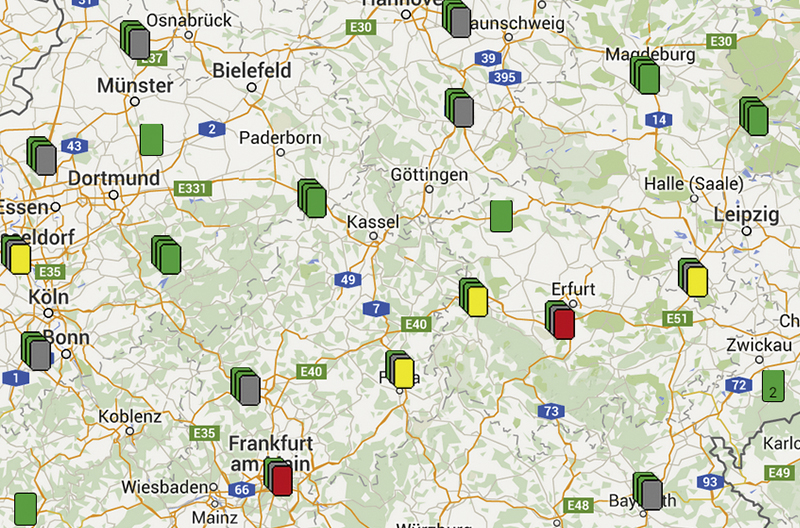

3. Delivery planning

Functions such as web map with tank locations and statuses, a calendar for planning delivery schedules and quantities, as well as a predictive consumption forecast enable optimized demand and logistics planning.

Additional information

Close