Batching tank for ointments

Level and pressure measurement and point level detection in ointment production in batch mode

Process data

Application

Your benefit

Recommended products

VEGABAR 83

Level, pressure and electronic differential pressure measurement with two pressure transmitters in the batching tank

- By measuring the pressure in the upper and lower region of the tank, both the gas head pressure and the level can be reliably monitored

- The thermally self-compensating METEC® measuring cell measures accurately and reliably – despite cleaning-related thermal shock

- Hygienic process fittings are ideal for use in sterile production processes

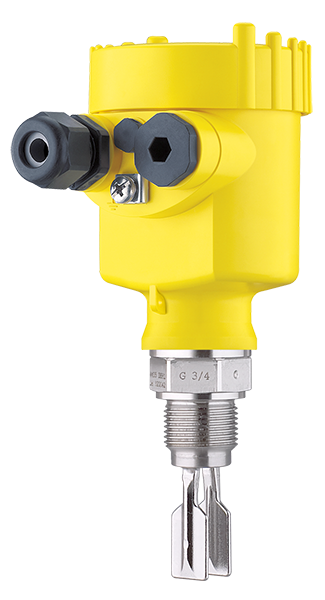

VEGASWING 61

Point level detection with vibrating level switches in batch operation

- Reliable detection of the limit level, regardless of the product or process properties

- Hygienically optimised process fittings ensure easy cleaning and maximum process safety

- Easy to install, even the very smallest process fittings are possible

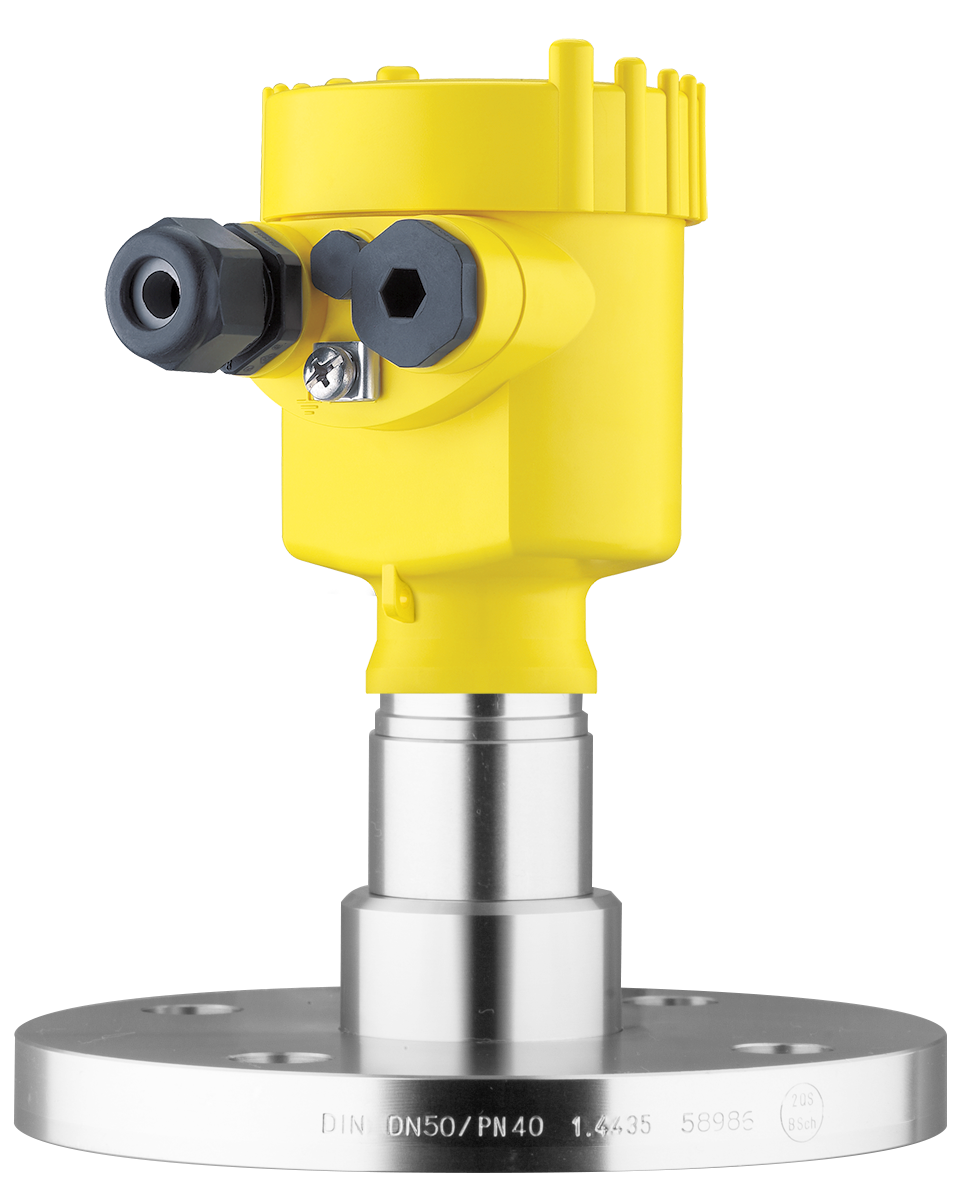

VEGAPULS 6X

Level measurement with radar in batch production

- The front-flush, encapsulated antenna is easy to clean and resistant to the extreme conditions of the SIP and CIP processes

- Strong focusing enables level measurement even with agitators present

- Reliable measurement despite buildup

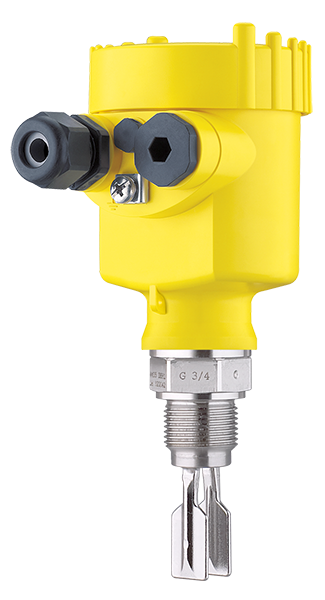

VEGASWING 61

Point level detection with vibrating level switches in batch operation

- Reliable detection of the limit level, regardless of the product or process properties

- Hygienically optimised process fittings ensure easy cleaning and maximum process safety

- Easy to install, even the very smallest process fittings are possible

Close