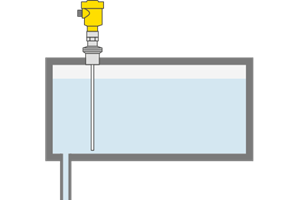

Batch holding tank on a filling system

Level measurement in the holding tank of a filling system

Process data

Measuring task:

Level measurement

Measuring point:

Tank

Measuring range up to:

0.3 m

Medium:

Conductive solution

Process temperature:

+20 ... +50 °C

Process pressure:

0 ... +15 bar

Special challenges:

Small levels, rapid level changes, Autoclaving

Application

Pharmaceutical products such as drugs and vaccines are held in batch filling holding tanks ready to be filled into injection vials under absolutely sterile conditions. After each batch, the holding tank has to be totally sterilized using an autoclaving procedure. During this process, the sensor is exposed to a pressure of 2.5 bar and a temperature of 130 °C for at least half an hour. The rapidly changing levels of the aqueous liquids are continuously monitored. The rapidly changing levels of the aqueous liquids require continuous and precise monitoring.

Your benefit

Reliable

Approved materials in compliance with FDA and EC 1935/2004

Cost effective

Reliable, continuous operation with absolute hygiene

User friendly

Standardized housing and adjustment concept

Recommended products

VEGAFLEX 83

Level measurement with guided radar in the holding tank of a filling system.

- Autoclavable version ensures absolute hygiene

- Short response time enables detection of quick level changes

- Wetted parts comply with material specification: Basle standard BN2

Measuring range - Distance

32 m

Process temperature

-40 ... 150 °C

Process pressure

-1 ... 16 bar

Close