VEGAPULS 64 level sensor monitors active ingredient concentration in pharmaceuticals

Hygienic design meets best measuring results

During operation, continually rotating scrapers ensure the vessel heating jacket is free of buildup. The focused beam of VEGAPULS 64 radar level sensor ignores these scrapers easily.

During operation, the scrapers continuously keep the heating jacket of the vessel free of buildup and encrustations. This is necessary because the extract, which is as viscous as honey, is concentrated very gently under vacuum. When the process is finished, the liquid solution has a significantly higher active ingredient content. At the same time, the continuous mixing by the agitator ensures a good heat exchange in the vessel contents.

Due to its strong focusing and unrivalled ability to "measure past" interfering vessel installations, VEGAPULS 64 is a perfect match for the pharmaceutical industry. With a 2'' clamp fitting, and its beam angle at only 6° – it is perfect for avoiding the scraper, the container wall and able to track the liquid level unimpeded all the way down to the vessel bottom. .

The advantages: Complete emptying of the vessel is guaranteed at the end of every batch. Any false echoes, like those generated at close range by the rotating crossbeam of the mixer, are intelligently suppressed by the sensor, thanks to its especially high dynamic range. This enables exact monitoring of the solution’s concentration throughout the evaporation process.

Certified by the US food industry, level sensor VEGAPULS 64 is the perfect solution for level measurement in pharmaceutical plants.

Applications

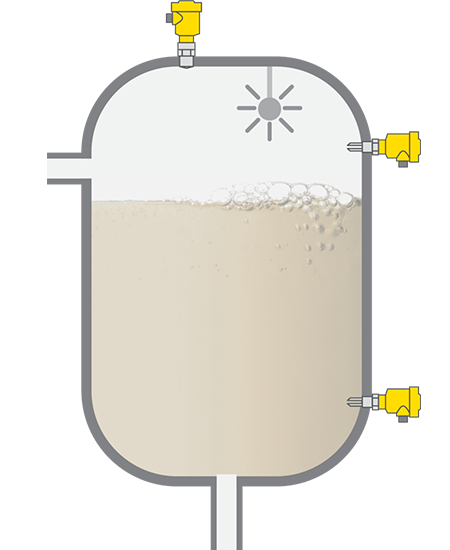

CIP system - cleaning agent storage tanks

Level measurement and point level detection in the cleaning agent storage tank of the CIP system

In the pharmaceutical industry, cleaning of process equipment takes place within the framework of a validated "Clean in Place (CIP)" process to ensure aseptic conditions are maintained in production equipment, tanks and pipelines. Sodium hydroxide or concentrated acids are frequently used as cleaning agents, which are held in storage tanks within the CIP system. They are diluted in a premix vessel prior to use. Level measurement enables safe storage and optimal usage of these cleaning agents. Point level detection serves as overfill and dry run protection.

Reliable

Approved materials in compliance with FDA and EC 1935/2004

Cost effective

Maintenance-free operation

User friendly

Simple mounting

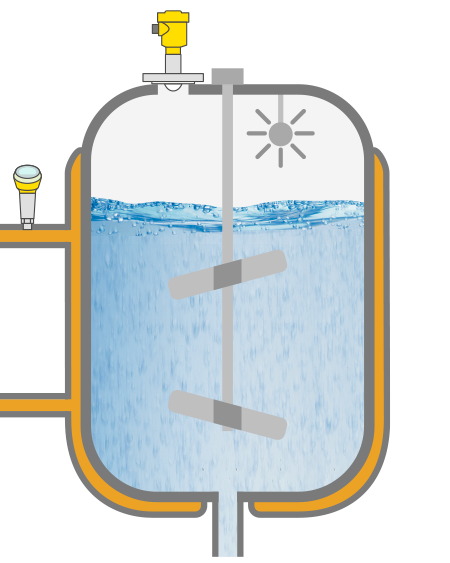

Mixing Vessel

Level measurement in the mixing vessel and pressure measurement in the supply line

Mixing vessels are applied for preparation, storage and transfer of a wide range of pharmaceutical products. These vessels are used for the manufacture of antibiotics, blood plasma products, and injection and infusion solutions. Following preparation, substances are transferred to a filling station. To ensure a reliable process, the liquid level in the mixing vessel must be reliably and continuously monitored.

Reliable

Certified hygienic design (3A/EHEDG) and approved materials according to EC 1935/2004 and FDA

Cost effective

Continuous operation with absolute hygiene

User friendly

Standardized adjustment, process data storable and transferable

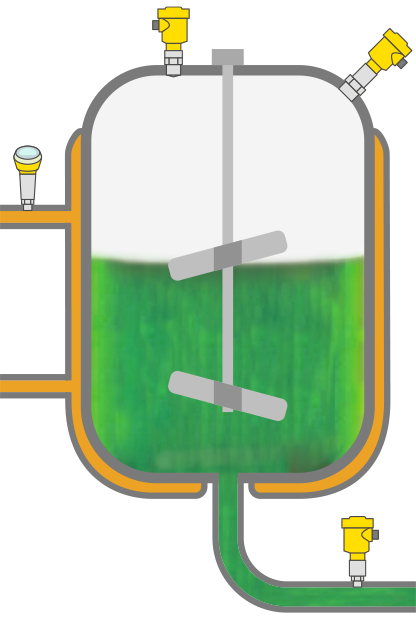

Bioreactor

Level and pressure measurement in the production of enzymes, proteins and antibodies

Some pharmaceutical companies use bioreactor vessels to cultivate particular cells or microorganisms required for certain treatments. The very high level of hygiene required means the vessels and all associated parts must be easy to thoroughly clean, because even the slightest contamination with other organisms can lead to an aborted production run. These reactors are mainly "batch-fed", where they are completely filled at the start and not emptied again until the process is completed. The pressure and level in the reactor have to be monitored continuously during process in order to obtain a high-quality yield.

Reliable

Unaffected by extreme process conditions

Cost effective

Reliable, continuous operation with absolute hygiene

User friendly

Easy adjustment and setup, as internals do not interfere

VEGAPULS 64 Focusing

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}