Tomato juice filling machine

Level measurement and point level detection in the filling machine

Process data

Measuring task:

Level and point level measurement

Measuring point:

Filling machine

Measuring range up to:

0.5 m

Medium:

Tomato juice

Process temperature:

+10 … +60 °C

Process pressure:

-1 … 0 bar

Special challenges:

Steam, condensate, buildup

Application

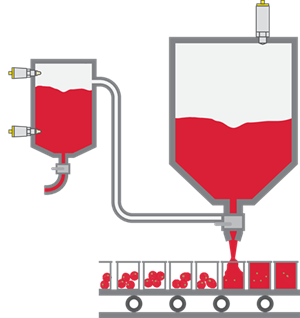

The empty cans enter the filling machine on a conveyor belt. As soon as an individual can reaches the appropriate position for filling, it is pulled in with the help of a pneumatic cylinder and filled under vacuum with natural tomato juice. The level of juice in the supply tank is monitored by a radar sensor. In each filling cycle, the same amount of tomato juice is sucked out of the supply tank. Reliable point level detection ensures that all cans are filled equally.

Your benefit

Safe

Approved materials according to FDA and EC 1935/2004

Cost effective

Not affected by buildup and water condensation

User friendly

Simple installation and setup

Recommended products

VEGAPOINT 21

Capacitive point level sensor for regulation of the tomato juice

- Reliable measurement ensures consistent filling of the cans

- 360° status display for quick and easy recognition of process status

- Good cleanability thanks to hygienic design

Measuring range - Distance

-

Process temperature

-40 ... 115 °C

Process pressure

-1 ... 64 bar

VEGAPULS 42

Compact radar sensor for continuous level measurement in the supply tank

- Reliable measurement ensures a sufficient supply of tomato juice

- Non-contact measuring principle for maintenance-free operation

- Simple integration into the plant thanks to IO-Link

Measuring range - Distance

15 m

Process temperature

-40 ... 130 °C

Process pressure

-1 ... 16 bar

Close