Homogenizer

Pressure measurement in a homogenizer

Process data

Measuring task:

Pressure monitoring and pressure switch

Measuring point:

Pipeline, hydraulics

Measuring range up to:

0 … 2.5 bar; 100 … 400 bar

Medium:

Milk, hydraulic oil

Process temperature:

+40 … +70 °C

Process pressure:

0.8 ... 2.2 bar; 100 … 400 bar

Special challenges:

Aseptic cleaning of the feed line, high-pressure measurement of the hydraulic oil

Application

In order to prevent the milk fat from settling on top of the milk, either just the cream or the whole milk is homogenised in the next step. This is where the cream or milk is pushed through micro-sized nozzles, which reduces the size of the fat globules and distributes them evenly in the liquid. The homogenised cream is then returned to the skimmed milk. Pressure in the feed line is monitored to control the homogenisation process. At the same time, pressure monitoring of the hydraulic oil ensures optimal control of the pistons.

Your benefit

Reliable

Reliable measurement ensures trouble-free operation of the homogenizer

Cost effective

Optimal control of the pistons through monitoring of the high-pressure pump

User friendly

Simple connection via standardised IO-Link

Recommended products

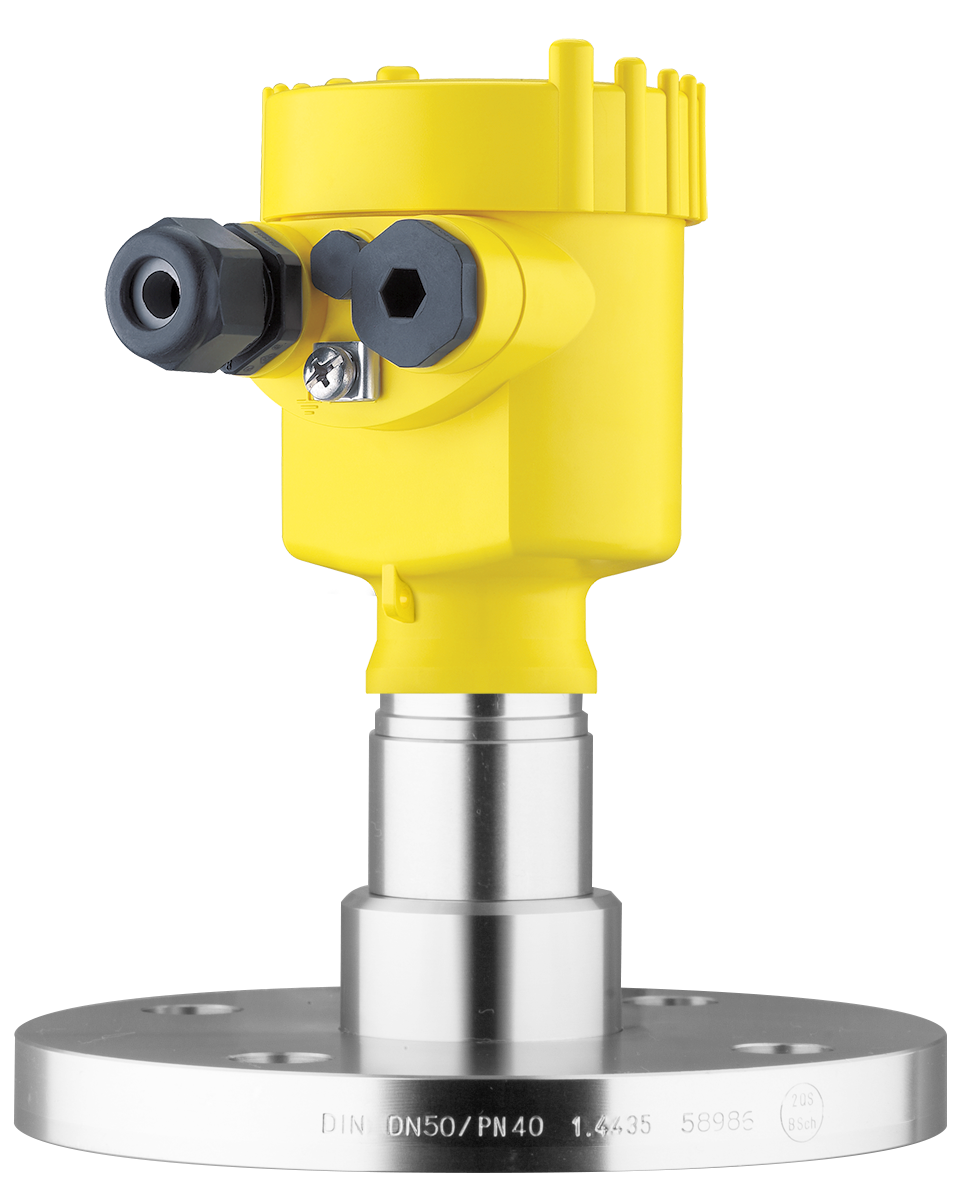

VEGABAR 83

Pressure transmitter for pressure monitoring in a homogenizer

- Robust measuring cell guarantees long-term stability

- Suitable for CIP cleaning processes, temperature resistant up to +150 °C

- Bluetooth communication for easy diagnosis

Measuring range - Distance

-

Measuring range - Pressure

-1 ... 1000 bar

Process temperature

-40 ... 200 °C

VEGABAR 29

Pressure switch for monitoring the hydraulic oil

- Highly overload resistant metallic measuring cell

- IO-Link connection for simple integration and user-configurable switching output

- 360° display of the switching status

Measuring range - Pressure

-1 ... 1000 bar

Process temperature

-40 ... 130 °C

Accuracy

0.3 %

Close