Beer tank

Level measurement in the beer tank

Process data

Measuring task:

Level measurement

Measuring point:

Tank

Measuring range up to:

5 m

Medium:

Beer

Process temperature:

+3 … +120 °C

Process pressure:

0 … +5 bar

Special challenges:

Humid environment, foaming

Application

During the brewing process, a thick layer of foam is always present in the beer tanks. Therefore usually two pressure transmitters are used for level measurement. One transmitter measures the head pressure, while the other at the bottom measures the total pressure. The level is precisely calculated from the differential between these two pressures. Hygienic process fittings are absolutely necessary for these sensors.

Your benefit

Reliable

Certified materials according to FDA and EC 1935/2004 regulations

Cost effective

plics® concept: short delivery time and standardized operation

User friendly

One measuring system, three measured values: level, pressure, temperature

Recommended products

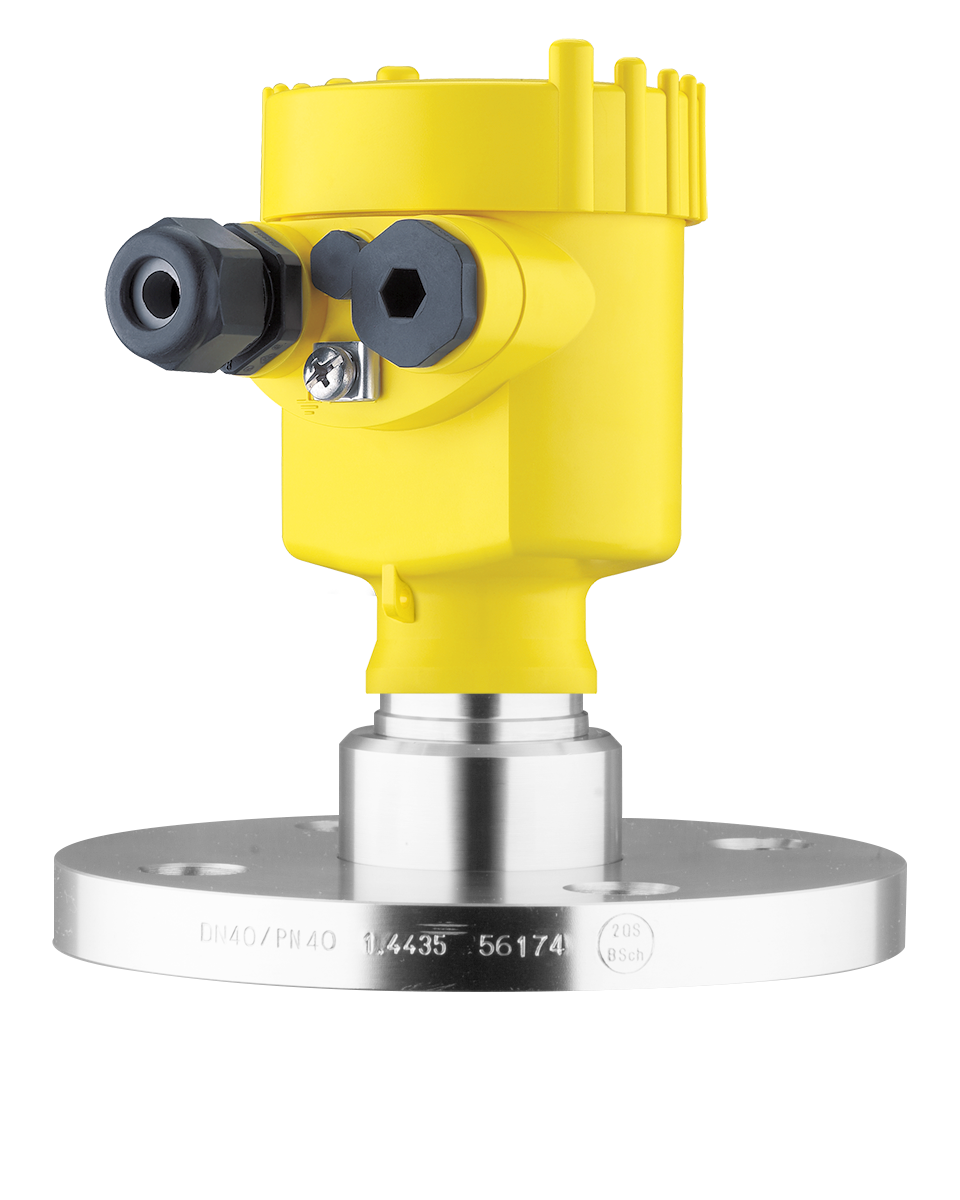

VEGABAR 82

Electronic differential pressure measurement for determining the level in the beer tank

- Temperature resistant, CIP capable, linear, overload proof and hysteresis-free

- Reliable level measurement, independent of foaming

- CERTEC® measuring cell of sapphire-ceramic® with gap-free surface meets the highest hygienic standards

Measuring range - Distance

-

Measuring range - Pressure

-1 ... 100 bar

Process temperature

-40 ... 150 °C

Close