Tanks for solvents

Level measurement, point level and pressure measurement in the storage and transfer of solvents

Process data

Measuring task:

Level and pressure measurement, point level detection

Measuring point:

Tank and pipework

Measuring range up to:

10 m

Medium:

Hydrocarbons, solvents

Process temperature:

+20 … +120 °C

Process pressure:

0 … +6 bar

Special challenges:

Media with very low reflective properties

Application

Low viscosity solvents can degrade many types of plastics. This places increased demands on the process instrumentation. A separate level detection system is required for protection against overfilling. It increases plant safety and ensures protection of human health and the environment.

Your benefit

Reliable

Reliable protection against overfilling

Cost effective

Independent of product and process characteristics

User friendly

Simple to set up and maintenance-free operation

Recommended products

VEGAFLEX 81

Level measurement with guided radar in the solvent tank

- Different sealing and housing materials ensure long-term and maintenance-free operation

- Reliable measurement even with changing media and foaming

- The SIL qualification (SIL2/3) and the approval for substances hazardous to water (WHG) allow use as part of an overfill protection system or safety instrumented system

- Maintenance-free operation of the facility

Measuring range - Distance

75 m

Process temperature

-60 ... 200 °C

Process pressure

-1 ... 40 bar

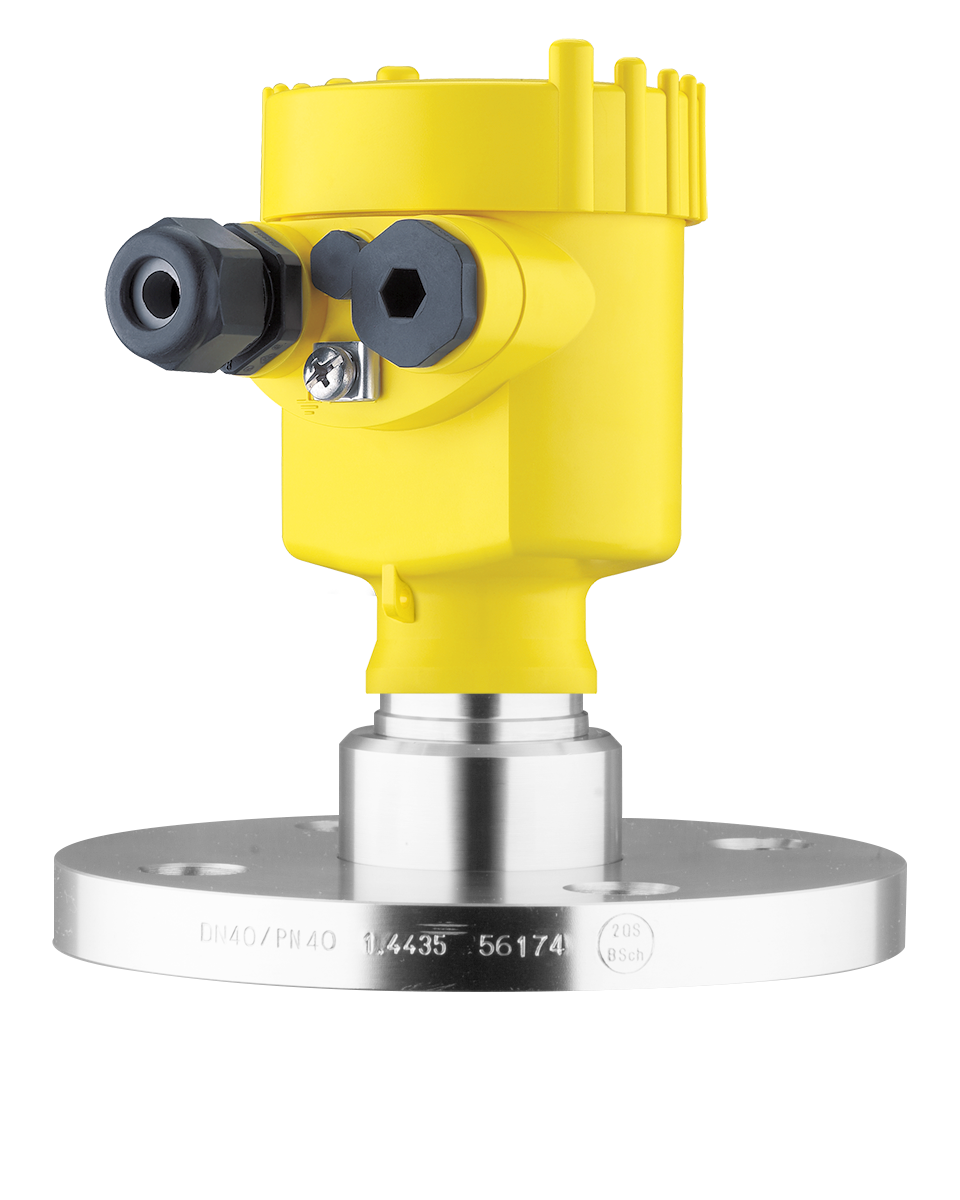

VEGABAR 82

Pump pressure measurement with pressure transmitter in the pump line

- Robust ceramic CERTEC® measuring cell withstands pressure surges or vacuum shocks in the pump line

- The high resistance of the measuring cell and the various process fittings ensure long-term, maintenance-free operation

- Reliable level measurement qualified to WHG and SIL

Measuring range - Distance

-

Measuring range - Pressure

-1 ... 100 bar

Process temperature

-40 ... 150 °C

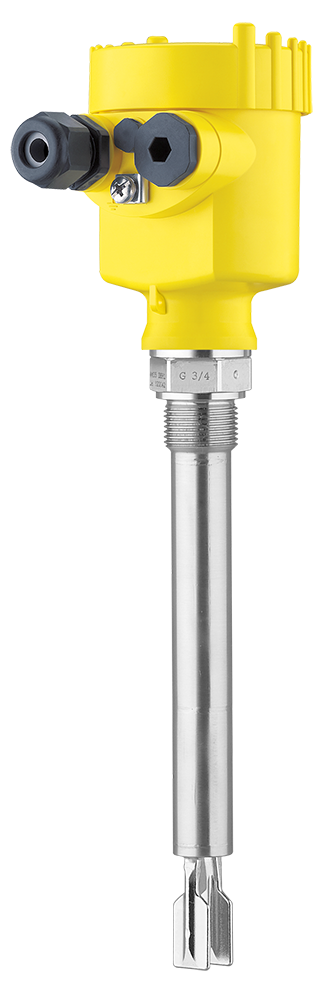

VEGASWING 63

Point level detection with vibrating level switch for overfill and dry run protection in the solvent tank

- Universally applicable for almost all liquids

- Additional safety thanks to glass feedthrough, which provides an additional process separation (Second Line of Defense)

- Simple setup without calibration

- Simple testing of the measuring system during operation via test button

Process temperature

-50 ... 250 °C

Process pressure

-1 ... 64 bar

Version

Standard

Hygienic applications

with gas-tight leadthrough

with tube extension

with temperature adapter

Close