Improve processes in sewage treatment plants with VEGA sensors

This province Walloon Brabant in the heart of Belgium has just under 410,000 inhabitants distributed among 27 municipalities. Wastewater disposal in this rural area is the responsibility of InBW (Intercommunale du Brabant Wallon), who is responsible for a total of 36 sewage treatment plants. This already reveals the first challenge: the large distances between the various plants. However, measurement in a sewage treatment plant involves further hurdles – such as vibration, condensation, dust, dirt and sludge, digester gases and measuring points that are difficult to access.

So what requirements do the sensors have to meet?

It depends, of course, on where the level and pressure sensors are deployed. But no matter if it’s flow in an open flume, a filter or a basin, one thing always applies: The measuring instruments must work accurately and uncomplicatedly, withstand extreme ambient conditions and function for as long as possible without maintenance.

VEGAPULS C 21 has proven itself over and over again in applications where a high protection class is required. The compact radar sensor delivers precise readings and is not affected by

- temperature fluctuations

- environmental influences like rain, fog or wind

- dirt and contamination

in any way. This gives radar measurement technology many advantages over ultrasonic-based measurement. Due to the good signal focusing of VEGAPULS C 21, the liquid level reflections can be better separated from false reflections, making the measuring results considerably more accurate. Another plus: VEGAPULS C 21, like other sensors of the series, has a fixed cable connection and is designed in protection class IP66/IP68. This enables a direct connection, for example to a PLC.

Where is VEGAPULS C 21 used?

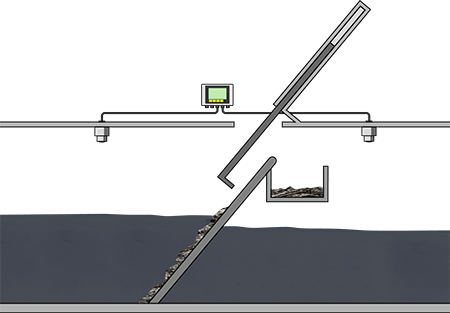

Screening system: Solids are sifted out of the water in various stages – in the coarse screen these are substances with a diameter of more than 25 millimetres. The fine screen is responsible for skimming off smaller solids. And this is exactly where VEGAPULS C 21 is used in Walloon Brabant: The radar sensor indicates the difference in water level between the front and the back side of the screen. The degree of contamination is determined via the differential measurement, triggering the cleaning of the screen when necessary.

Applications

Coarse and fine screens

Differential water level measurement for control of screen raking

Mechanical cleaning removes entrained floating matter with screens or sieves. This protects the downstream process stages from buildup, clogging and abrasion. Solids with diameters greater than 25 mm are trapped in the coarse screens, compressed in a press and then disposed of. Finer secondary screens remove smaller residual materials. Measurement of the difference in water level between the front and the back of the screen determines the degree of contamination and initiates the cleaning of the screen when necessary.

Reliable

Reliable control of screen cleaning

Cost effective

Non-contact and wear-free measurement

User friendly

Maintenance-free operation of the system

Applications

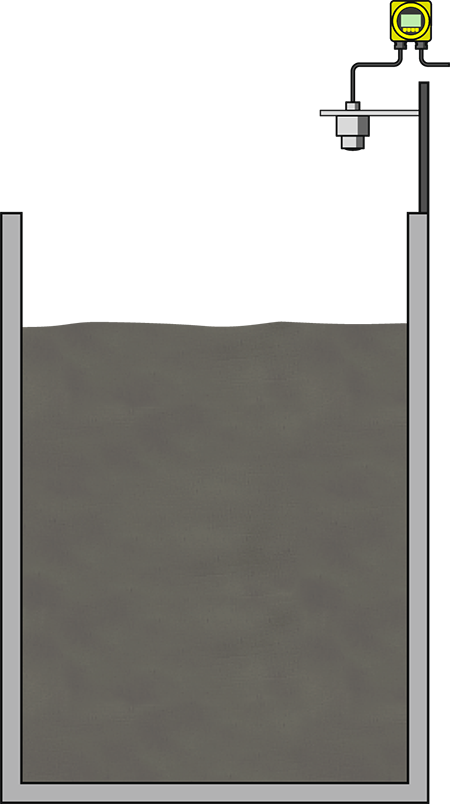

Sludge thickening tank

Level measurement in a sludge concentration tank

Before the sludge enters the digestion tower, it is stored in large vessels. During storage, the sludge is dewatered and thickened sometimes scrapers and agitators are used to accelerate the process.

Reliable

Reliable content measurement in the sludge thickening tank

Cost effective

Non-contact measurement ensures maintenance-free operation

User friendly

Simple installation and setup

What other VEGA instruments can be found in the sewage treatment plants?

How are the measurement data read and processed?

Those responsible at InBW applaud the efficiency, simplicity and versatility of VEGAPULS C 21. The ability to adjust the VEGA instruments via Bluetooth or to calibrate the sensors makes the everyday work of the sewage treatment plant employees much easier – especially in overcoming the great distances.

Related industries

Wastewater treatment

Drinking water supply

Products

Export this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}