Reliable measured values despite cramped conditions

Achental, Inntal, Zillertal – these Tyrolean valleys on the northern edge of the Alps are extremely popular with tourists. Their unique nature and idyllic location attract around 8.5 million visitors every year. Countless hotels, guest houses and restaurants, as well as small businesses such as alpine dairies and yoghurt producers, do their best to make sure the guests have a completely enjoyable experience.

The local sewage treatment plants, however, face a special challenge. Wastewater produced in the area has a high fat content. Although cleaning out and processing this material is not a problem technologically, the process conditions are quite challenging for level sensors. The high fat content in the wastewater creates a lot of foam – this makes the liquid levels in the various basins and pump shafts difficult to detect.

At one with nature

The wastewater is fed to the Strass sewage treatment plant via a 161 km-long sewer network and 14 pumping stations distributed throughout the association’s territory. “Thanks to the state-of-the-art process technology in our facilities, we’ve achieved absolute top performance in the entire pan-European wastewater sector,” adds Brandacher, clearly with great pride. As a result, the total energy consumption of the wastewater treatment plant has dropped noticeably since 2003, despite increasing loads. The specific energy consumption in kWh per inhabitant and year has been reduced from an initial 30 kWh to approximately 20 kWh.

On the way to the sewage treatment plant

New compact level sensor in use

The compact series is intended for simple, non-contact level measurement where a high protection rating is required. They are particularly suitable for use in water treatment, pumping stations and rainwater overflow basins, as well as for flow measurement in open flumes and river level monitoring. The sensor delivers exact measuring results without effect from the medium, the process or the ambient conditions, is maintenance free and thus ensures high plant availability. It is also based on VEGA’s 80-GHz radar technology, which has been revolutionizing level measurement for several years now. This is thanks to the extremely narrow beam angle, which makes it possible for the instrument to deliver very precise measuring results even in cramped measuring situations, in extremely dirty environments or in containers with many internal installations.

Exactly such environments exist in the two pump shafts in Hart and Buch in Zillertal. “All the adversities one can imagine are present in the pump shafts. Aerosols, moisture, cold, dirt, etc. and of course the huge quantities of fatty material,” explains Brandacher further.

In Hart, the pump shaft has a cross-section of about 3 x 2.5 metres and a depth of 4 metres. In Buch the shaft is round, with a diameter of 2 metres and a depth of 5.5 metres. The situation here is particularly difficult because of the low level of impoundment. The pump is effectively in continuous operation, switching on and off up to 100 times a day. An ideal application site for the new VEGAPULS C 21/C 22 sensor series. The sensors work reliably even with foam, of which there is plenty in the AIZ network, and with buildup on the shaft walls.

Both sensors have been in use since March 2020, delivering the required level data continuously without any problems. A development that is entirely in the spirit of Brandacher’s philosophy: “Sensors are there to measure and nothing else.”

Related products

Related industries

Wastewater treatment

Related applications

Pumping station

Level control in a pumping station

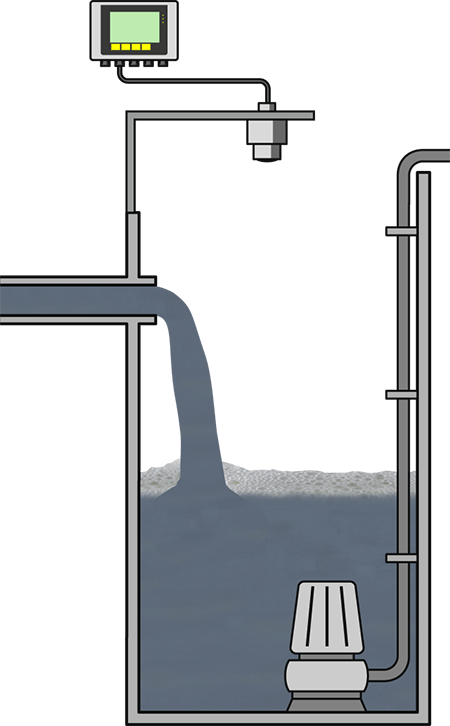

Wastewater from households and businesses, together with surface water, is carried to the wastewater treatment plant via an extensive sewer network. If the natural gradient is not steep enough, numerous pumping stations are required to create a sufficient height difference. The level measurement in the inlet shaft is used for cost-effective control of the pumps.

Reliable

Reliable measurement of the level

Cost effective

Pump switching ensures optimal operating times

User friendly

Maintenance-free, trouble-free operation

Related articles

Compact radar sensors deliver reliable level values independently of process and environmental influences

Read more

New compact radar level instruments defy buildup to deliver reliable measurement

Read more

Compact radar sensors without dead zone deliver reliable level values in small vessels

Read more

Radar sensors with strong focusing ensure more precise values in continuous level measurement

Read moreExport this article

Download as PDFShare this article

Comments ({{comments.length}})

{{getCommentAuthor(comment, "Anonymous")}} {{comment.timestamp | date : "dd.MM.yyyy HH:mm" }}

{{comment.comment}}